Pepperl + Fuchs IO link solution paves the way for industrial digital interconnection

Release date:2019-05-11 Number of views:

As early as 2014, Pepperl + Fuchs proposed "SENSORIK 4.0" ®” In order to promote the process of manufacturing factory field layer in the development of "industry 4.0". Under the requirements of the new era, in addition to the communication with the parent control unit, each production part should have the ability to communicate with the parallel equipment in the same network. Sensors will be the core components of nuclear equipment to achieve this function, and will also give the equipment the functions of self diagnosis, self debugging and mutual service.

IO link technology is the key to open SENSORIK 4.0 ® It's the gate of the city. As a field level developing communication protocol, the data from machines and systems are consistent with the concept of industry 4.0, which brings potential new equipment upgrade. Economic production technology will participate in the future industrial production through IO link technology to ensure the flexibility and reliability of production.

IO link paves the way for digital network

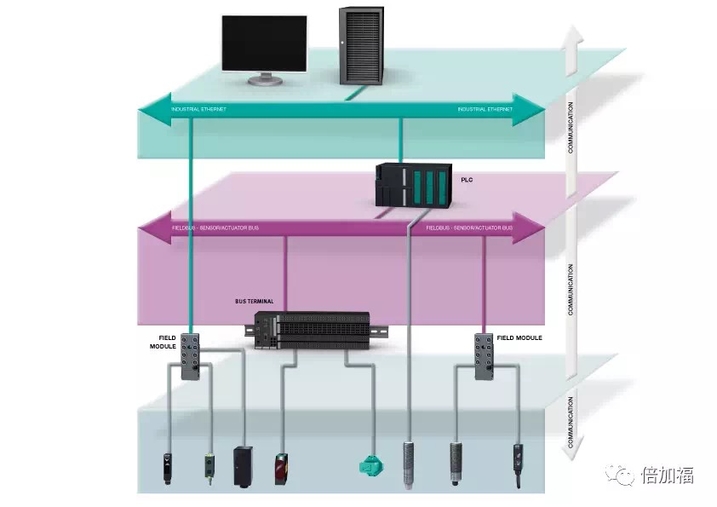

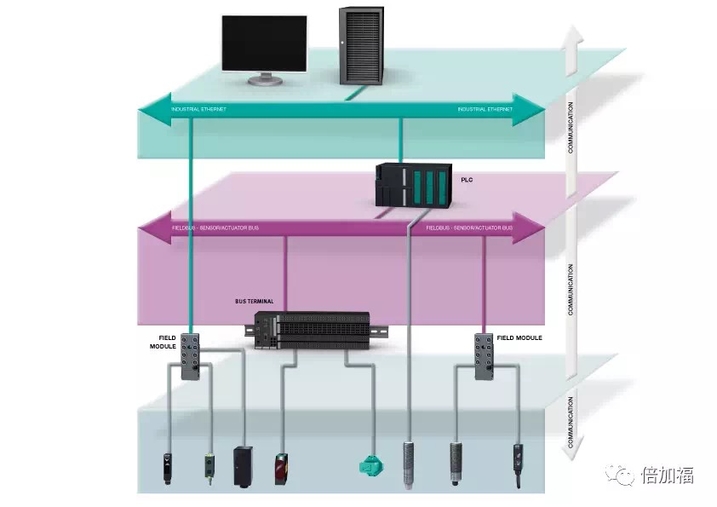

IO link can realize seamless communication and digital data transmission from control level to sensor. Intelligent devices can give full play to their potential through IO link, paving the way for industrial 4.0 automation technology. International standard interface embodies the value of all stages from factory design to installation, operation and maintenance through continuous cost reduction. Standard device description files (iodds) and device parameters ensure the convenient configuration and simple integration of IO link sensors and actuators through software tools.

Intelligent and transparent parameter management can enhance the flexibility of applications and reduce downtime. Even for complex product alternation and batch change, parameters can be adjusted quickly and conveniently. Through the direct and transparent management of sensors, users can obtain parametric options and equipment diagnosis functions for predictive maintenance.

The IO link device is at the automation level

The IO link device is at the automation level

The main station module with gateway function connects the sensor and actuator together as a node on the bus I / O, and then transmits it to the control network through the bus interface, realizing the automation integration based on Io link system.

IO link system solution

From industry 4.0 to intelligent manufacturing, the production line will also enter the intelligent factory: production equipment interconnection, object identification and positioning, equipment status monitoring, product remote maintenance, etc. Among them, intelligent sensing technology from the bottom ensures the integrity and transparency of data, pepper + Fuchs SENSORIK 4.0 ® Technology for all kinds of production equipment to provide intelligent sensors to ensure the flexibility and reliability of production.

Pepperl + Fuchs provides you with an end-to-end IO link system solution, including various IO link sensors and Ethernet IO modules integrated with IO link master. This combination contributes to the seamless communication between the field level IO link equipment and the upper management and control system.

China

China English

English